With environmental consciousness becoming increasingly crucial, the industrial manufacturing sector stands at a crossroads. With pressure to reduce carbon footprints and embrace sustainable practices, the industry faces both challenges and opportunities in shaping a greener future. With the evolving landscape of sustainability in this industry, manufacturers must explore the avenues for progress and the obstacles to benefit them in the long run.

Steel King Industries

Steel King is known for offering pallet racking and material handling products with top quality and durability. Beyond these attributes, their products are increasingly manufactured with a strong focus on environmental sustainability and employee health and safety.

Their sustainability efforts span across its operations, from sourcing raw materials to manufacturing and facility management. Purchasing North American steel and recycling all scrap steel contribute to their sustainable approach. Effectively reducing both carbon footprint and waste. Steel King also emphasizes sourcing materials from nearby locations and employs “mini mills” that exclusively utilize recycled scrap in manufacturing. Alongside material sourcing, Steel King has adopted energy-efficient measures, including the use of alternative powder coating materials and repurposing excess heat.

Steel King’s commitment to sustainability extends to their new headquarters in Stevens Point, Wisconsin. Where they chose to repurpose an existing structure instead of constructing a new one. This decision not only minimizes environmental impact but also maintains proximity for employees and includes energy-saving elements such as fewer parking spaces and a redesigned green area for natural runoff filtration.

To guarantee accountability, Steel King monitors its safety and sustainability efforts and intends to release a yearly sustainability report. This report will not just motivate other companies but also fulfill the rising request from major customers for such records, showcasing Steel King’s commitment to sustainable business practices.

Renewable Lubricants

Renewable Lubricants™ focuses on environmentally friendly products while ensuring top-notch performance. Their bio-based engine oils, derived from plant-based synthetic base oils, serve as direct substitutes for petroleum synthetics such as Mobil 1. These alternatives offer the same high performance, excellent cold weather performance, and compatibility with motor oils.

Despite petroleum’s dominance in the motor oil market, Renewable Lubricants™ seeks to challenge this norm. While acknowledging the trust customers have in traditional petroleum products, the company stresses the significance of transitioning to bio-based options for environmental sustainability.

When the US Environmental Protection Agency (EPA) introduced the Vessel General Permit (VGP) in December 2013, requiring the use of environmentally acceptable lubricants (EALs) in oil-to-sea interfaces on vessels in US coastal waters and Great Lakes, Renewable Lubricants™ responded by creating a full product line that complied with these regulations. This move aligns with their commitment to using renewable materials for a greener future.

Filtration Group

Filtration Group is dedicated to sustainability and environmental responsibility. Recognizing the significance of preserving air quality, they prioritize this not only for the well-being of their employees but also for the overall health of our planet. They acknowledge that sustainability requires collective effort and they actively engage with their clients to collaborate to achieve shared sustainability goals. This can involve various initiatives such as waste reduction, energy conservation, and carbon footprint reduction, tailored to meet each client’s specific needs.

They emphasize the importance of regular maintenance, advocating for routine filter replacement or cleaning. There are many ways that directly impacts energy consumption and savings:

- Improved HVAC Efficiency: Clean air filters facilitate proper airflow, enhancing HVAC system performance. Clogged filters restrict airflow, forcing the system to work harder and consume more energy. Regular filter maintenance ensures optimal airflow, reducing energy demand.

- Reduced Energy Consumption: Clean filters improve indoor air quality and allow the HVAC system to reach and maintain temperatures efficiently. This reduces runtime and energy consumption, leading to cost savings on utility bills.

- Extended HVAC Lifespan: Clean filters prevent dust and debris from damaging internal components, extending the system’s lifespan. This reduces the need for frequent repairs or replacements, contributing to long-term energy savings.

At FG, they are not just providing filtration solutions; they are pioneering a sustainable future—one filter at a time.

ASC Engineered Solutions

ASC Engineered Solutions plays a role in sustainability within the energy sector through its comprehensive offerings and expert services. Sustainability in this context encompasses not only environmental considerations but also economic and social dimensions.

- Resource Efficiency: By providing OEM replacement valve trim parts and offering custom manufacturing and refurbishment services, ASC Engineered Solutions enables energy facilities to extend the lifespan of their infrastructure. This reduces the need for frequent replacements and minimizes the consumption of raw materials, contributing to resource conservation and minimizing waste generation.

- Energy Efficiency: The precision-engineered products and solutions offered by ASC Engineered Solutions help optimize the performance of energy facilities. By ensuring that valves and fittings operate at their peak efficiency, energy losses can be minimized, leading to reduced energy consumption and lower carbon emissions per unit of energy produced.

Long-Term Reliability: By providing high-quality products and engineering expertise, ASC Engineered Solutions supports the reliability and safety of energy infrastructure. This is critical for maintaining uninterrupted energy supply, avoiding costly downtime, and ensuring the resilience of energy systems in the face of environmental challenges or disruptions.

Feit Electric

Provides smarter, safer and longer lasting light. Allowing you to upgrade residential, commercial, and outdoor spaces with innovative lighting that will help you save on energy cost.

LED (Light Emitting Diode) bulbs are more energy-efficient and last longer than traditional incandescent bulbs. LED bulbs use up to 75% less energy and last up to 25 times longer than incandescent bulbs. Although LED bulbs can be more expensive upfront, they save money in the long run by reducing energy costs and the need for frequent bulb replacements.

Look for Bulbs with the Energy Star label. This label is given to products that meet strict energy efficiency guidelines set by the US Environmental Protection Agency (EPA). Upgrading to Energy Star-certified bulbs can save energy and money without sacrificing performance or quality.

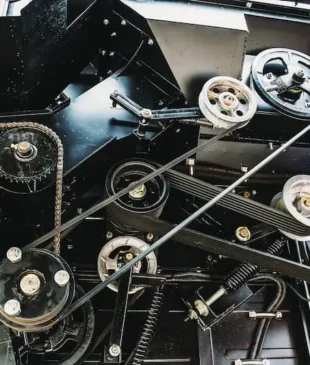

Bando

V-Belts can be a great way to improve energy efficiency, which ultimately leads to energy savings through reduced friction, and maintenance. Proper installation and tensioning minimize energy loss, while their durability and elasticity extend equipment life and sustainability.

A Bando Raw Edge Cogged V-belt grips the sheave of sidewalls better, minimizing slips, which again in turns increases efficiency. Sheaves with as little as 1/32 of wear will cause belts to slip excessively. Replacing has a payback of four months when compared to the cost of electricity loss due to inefficiency of the drive.

Most standard wrapped V-belt drives operate at an efficiency rate of about 93%, when properly installed and maintained. Their Power Ace Cog and their Power King Cog are proven to improve drive efficiency by 2-3% as compared to the standard wrapped V-belt. This is due to the raw edge grips that the sheave sidewalls better, reducing the bending resistance. Therefore, running cooler and lasting longer.

For Example: If a 100-horsepower supply air fan motor, utilizing a 93% efficient wrapped V-belt, runs continuously with an average load of 75%, consuming 527,000 kilowatt-hours per year, what would be the yearly energy and monetary savings if the wrapped V-belt were replaced with a 95% efficient cogged V-belt? Electricity costs are $0.10 per kilowatt-hour

Energy Savings

Annual Energy Use X (1-n1/n2) + 527,000 kWh/year X (1-95/98) + 16,132 kWh/yr

Cogged Annual Cost Savings

16,132 kWh X $0.010/kWk = $1,612/yr