The last couple of years presented us with the challenges of living through, and coming out of, a pandemic. As a result, better indoor air quality has become a top priority, and air filters are one area in which you can make positive improvements. During the pandemic, the CDC recommended that you upgrade your air filter to a MERV 13, or as close to it as possible.

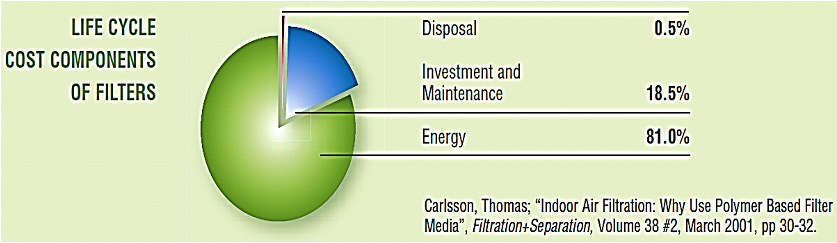

When choosing a filter, consider the trade-offs. Typically, as you increase the efficiency of an air filter, you increase the energy cost to push the air through the air filter. The key is to know your goals and the impact of each option. For example, energy makes up 81% of the Total Cost of Ownership (TCO) of the life of an air filter. As technology advances to reduce energy costs, these costs tend to have a greater impact on the TCO. By changing the format of the filter, you can achieve lower resistance, resulting in lower energy costs.

Consider these 4 cost factors:

• Product Purchase Cost

• Energy Costs

• Labor Costs

• Disposal Costs

Each of these four factors make up the TCO. Ranking these factors helps identify the best filter for your specific application. Here are three examples of a customer using the most common filter, a MERV 8 Pleated Filter (ASHRAE recommends MERV 8 or greater for any units with air conditioning coils). There are multiple options to consider. We’ll apply the following assumptions:

• Current Pleated filter is changed every 90 days (quarterly).

• No current issues are present in the system.

• Using standard 24 X 24 X 2 filters.

Pleated, Merv 8, Standard Capacity, Self-Supported (Lowest Purchase Price)

⦁ Robotically Manufactured.

⦁ Very consistent pleat spacing.

⦁ Entry level price point.

⦁ Meets ASHRAE recommendations for air conditioning coils.

⦁ Typical recommended change is every 90 days (quarterly).

⦁ No wire backing to prevent cut risks during installation and disposal.

⦁ Media has built in memory and will hold the pleated format.

Pleated, Merv 8, High Capacity, Self-Supported

⦁ Robotically Manufactured.

⦁ Very consistent pleat spacing.

⦁ Meets ASHRAE recommendations for air conditioning coils.

⦁ 30% more media than Standard Capacity resulting in 30% longer life.

⦁ If Standard Capacity last 90 days, High Capacity will typically last 120 days.

⦁ No wire backing to prevent cutting risks during installation and disposal.

⦁ Media has built in memory and will hold the pleated format.

Pleated, Merv 10, High Capacity, Wire Backed

MERV 10 captures more particles reducing downstream risks.

⦁ Lowers resistance resulting in lower energy costs.

⦁ Meets ASHRAE recommendations for air conditioning coils.

⦁ 30% more media than Standard Capacity resulting in 30% longer life.

⦁ If Standard Capacity last 90 days, High Capacity will typically last 120 days

As we review each of the cost drivers, you can determine what is most important to you and your application. Notice that the “Best” air filter will vary depending on which cost driver is most important.

| Pleated Air Filter | Purchase Price | Energy Cost | Labor Costs | Disposal Cost |

|---|---|---|---|---|

| MERV 8, Standard Cap., Self-Supported | Best | Good | Good | Better |

| MERV 8, High Capacity, Self-Supported | Better | Better | Better | Best |

| MERV 10, High Capacity, Self-Supported | Good | Best | Best | Good |

Now, let’s look at how these variables change when we consider multiple staged filtration. Here, the pleated filter is sacrificed to extend the life of a much higher efficiency, higher cost air filter.

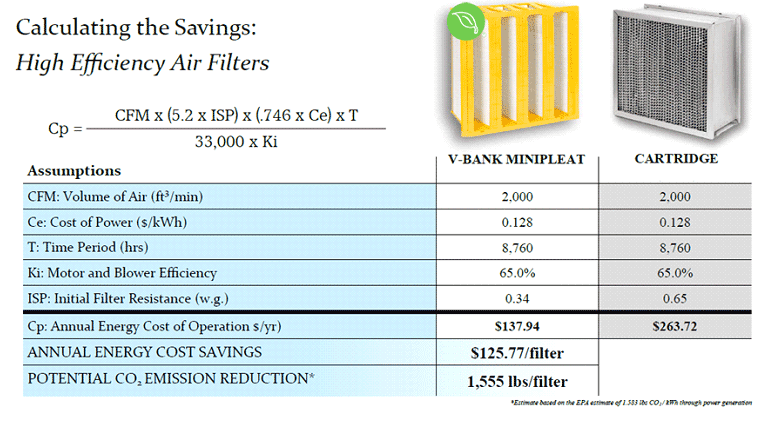

In this example, we’ll review the energy costs of using a Cartridge Filter and a V-Bank Minipleat. Both filters are 24″ x 24″ x 12″, Merv 15.

As you can see, the V-Bank Minipleat saves $125.77 per year, per filter, in energy costs. These savings will nearly cover the entire cost of the air filter upgrade. The lifespan of a filter is also a factor, as a long-lasting filter can reduce the number of changes needed.

Identifying the best air filter for your needs can be challenging, but MSG, Inc. and our manufacturing partner, Filtration Group IAQ, are happy to assist in this process. As mentioned, each scenario is unique, and our solutions are built specifically around you to achieve the optimal product for your application. Additional services we may use in identifying the best solutions include:

⦁ Filter Life Test

⦁ Lab testing a filter prior to disposal to determine if there is life remaining in the filter.

⦁ Site Audit

⦁ Going on-site to walk through air handlers, to achieve a better understanding of challenges.

Between the high-quality manufacturing expertise of Filtration Group IAQ and our Regional Sales Managers at MSG, Inc, we’re confident that we can help you determine the best product to achieve your goals.