Regular maintenance of industrial equipment is crucial for preventing unexpected breakdowns and avoiding costly repairs. It ensures smooth, uninterrupted operations and prioritizes safety by minimizing the risk of equipment malfunctions that could endanger personnel. Additionally, routine upkeep enhances operational efficiency, leading to improved performance and lower energy consumption. By extending the lifespan of equipment, regular maintenance offers a better return on investment and reduces long-term costs.

Here’s how partnering with the right manufacturers can maximize these benefits and save you money:

Renewable Lubricants

Renewable lubricants, derived from sustainable resources, provide performance superior to traditional petroleum-based options, all while significantly reducing environmental impact. When paired with regular maintenance, these lubricants optimize equipment performance and longevity. Regular upkeep not only ensures that equipment operates at its best but also amplifies the benefits of renewable lubricants, such as enhanced environmental sustainability and improved safety. This combination boosts operational efficiency and cost-effectiveness while reinforcing your commitment to eco-friendly practices and a safer work environment.

Products such as Renewable Lubricants’ Bio-Synxtreme® 100% Synthetic Lubricant, Bio-EP Gear Oil, and Eco-ATF Automatic Transmission Fluid are excellent examples of how these advanced formulations can enhance operational efficiency.

Renewable Lubricants’ Bio-Synxtreme® 100% Synthetic Lubricant- These gear oils are biodegradable to minimize their impact on the environment. They lubricate, cool, and protect gear teeth in marine and mobile equipment operating in environmentally sensitive areas.

Bio-EP Gear Oil- With a super high viscosity index (VI), Stabilized HOBS formulas deliver lighter viscosity at lower start-up temperatures for better energy efficiency and superior protection at higher operating temperatures compared to mineral-based options. These advanced formulas feature enhanced additives to resist wear, oxidation, rust, foam, and water, and provide improved bearing and gear protection against scuffing and micropitting.

Eco-ATF Automatic Transmission Fluids- Enhances performance in automatic and powershift transmissions, providing smooth shifting, high torque capacity, and durability. It is also effective in hydraulic systems, offering reliable performance and protection. Reduces environmental impact, improves wear protection, reduces friction, and maintains efficiency at high temperatures, making it a versatile and eco-friendly choice for automotive and industrial applications.

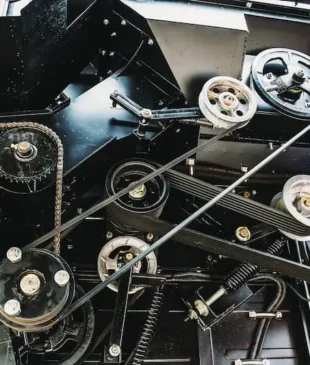

Bando Belts

Bando belts are essential for maintaining the efficiency and reliability of industrial equipment due to their superior performance and durability. In demanding industrial environments, equipment belts play a critical role in power transmission and operational smoothness. Bando belts are engineered to withstand high loads, extreme temperatures, and harsh conditions, ensuring consistent performance even under the most strenuous circumstances. Their robust construction helps prevent slippage, reduces wear and tear, and minimizes the risk of unexpected equipment failures, which can lead to costly downtime and repairs.

V-Belts: Bando V-belts are designed to handle high loads and resist wear in tough conditions, ensuring smooth power transmission and operational efficiency. Their robust construction helps prevent slippage and reduces wear and tear, minimizing the risk of unexpected equipment failures. This reliability translates to fewer maintenance issues and a lower total cost of ownership.

Timing Belts: Bando timing belts are crafted to offer precise power transmission and exceptional durability. They are built to withstand extreme temperatures and harsh conditions, providing consistent performance and preventing costly downtime. Their advanced design ensures accurate timing and reduces maintenance requirements, supporting uninterrupted operations and enhancing overall productivity.

Choosing Bando belts—whether V-belts or timing belts—means investing in top-tier quality and dependability. By incorporating Bando belts into your maintenance routine, you ensure that your equipment operates efficiently and reliably, ultimately boosting productivity and reducing the likelihood of unexpected disruptions.

Filtration Group

Regular maintenance of air filters is essential for sustaining optimal performance, energy efficiency, and equipment longevity. Clean filters also contribute to good air quality, safety, and cost savings. Regularly changing or cleaning filters reduces energy consumption, lowers operating costs, and prevents costly repairs. Efficient filters ensure smooth equipment operation, reducing the likelihood of downtime and enhancing overall health by maintaining clean indoor air.

Regular maintenance of HVAC filters is especially crucial for ensuring the optimal performance, energy efficiency, and longevity of your HVAC system. Filters are designed to capture airborne particles such as dust, pollen, pet dander, and mold spores before the air is circulated through your home and facilities. Conversely, clogged or dirty filters impede airflow, forcing the system to work harder to heat or cool your home, leading to increased energy consumption and higher utility bills. By regularly changing or cleaning the filters, you can significantly reduce energy costs and prevent unnecessary strain on the system, which in turn helps avoid costly repairs and extends the lifespan of the equipment.

Pleated air filters are excellent for maintaining equipment upkeep due to their superior filtration efficiency and extended surface area. They feature a series of folds that create more surface area for trapping airborne particles and also allows for greater airflow, reducing the strain on your HVAC system. Because pleated filters can hold more dirt and debris before becoming clogged, they need to be replaced less frequently, leading to fewer maintenance interruptions and lower long-term costs. Extending the lifespan of your equipment and maintaining its efficiency.

Rapid Air

Rapid Air compressed air filters are highly effective for regular maintenance due to their ability to significantly enhance air quality and protect equipment. These filters are designed to efficiently remove contaminants such as dust, dirt, water, and oil from compressed air, ensuring that only clean air reaches your machinery. This not only helps in maintaining the efficiency and longevity of pneumatic tools and equipment but also reduces the risk of wear and damage. By preventing contaminants from affecting your system, Rapid Air filters minimize the likelihood of unexpected breakdowns and costly downtime, leading to overall cost savings.

They also contribute to a safer and more compliant working environment by ensuring that the compressed air meets industry standards. Additionally, these filters are user-friendly and designed for easy maintenance, allowing for straightforward replacement or cleaning as part of a regular upkeep routine. Overall, Rapid Air filters support the smooth operation of your compressed air system, making them an essential component of effective and efficient maintenance practices.

Conclusion

In summary, regular maintenance of industrial equipment is a fundamental practice that ensures operational efficiency, enhances safety, and extends equipment lifespan. By committing to consistent upkeep, you can avoid expensive downtime, minimize repair costs, and meet industry standards. A proactive maintenance strategy not only protects valuable assets but also supports productivity and long-term success.

Contact MSG today to explore how we can help you with these maintenance solutions and more.